Tuesday 29 May 2012

synopsis

My concept for my first collection was about the sewing machine. I focussed on the mechanics of the sewing machine and how sterile and impersonal it can be, contrasted with memories and human interaction around it, making it a much more personal item. The collection was heavily influenced by the developed idea of a human morphing into a mechanical machine and the contrast between the two extremes. I found this idea very intriguing and it was interesting to design for. The goal of the collection was to successfully portray these themes like what was done for the first collection. For this updated diffusion range I wanted to portray these ideas within each garment so they could be independent from each other, unlike what was seen in the first collection.

My refined collection developed from the first collection is for Autumn/Winter 2012 and for the middle to high end markets (a diffusion line). It is a menswear collection for the 15-25 age range. The refined collection has a definite focus on the sewing machine and the mechanics of the machine, however I focussed a lot more on the silhouette of the sewing machine and it's placement in relation to the body in comparison to the first collection which was more about the details. The garments subtly hint that they were influenced by the sewing machine and it's mechanical nature rather than being too obvious and statement. The market influenced my decision for this greatly, because the collection needed to be wearable and socially acceptable, compared to the more expensive high market range which could be very unique and push the boundaries greatly. The diffusion line has boundaries because of what my customers are willing to wear and pay for, and also what society chooses is appropriate. The silhouette and shapes of the garments relate to the curved and square shapes of the sewing machine. These shapes have been emulated within the garments to give my garments a consistency. The target market and my brand influenced this because I want my brand to be recognisable and have a signature look, and so do my customers. Because if someone, specifically someone who is involved in fashion such as a blogger, is wearing a well respected brand they want others to know that they have a garment from there. The shape of the garments is also consistent because then my customers can mix and match any of the garments and make a number of successful outfits. The shape of the jackets was also influenced by my target market. They are made suitable for winter by having long sleeves and being knee length. Layering of fabric is located around chest to keep chest warm and free from wind and cold so the customer can stay healthy. Shape is also between fitted and loose, so that the customer can look thin but also is able to wear multiple layers underneath for warmth.

The garments are on the pricier side of the diffusion market range, but are still affordable to the customer base. The target market should consider my garments to be on trend and a good in season purchase. I want them to be able to continue wearing the garments for years. I hope that the customer considers my garments as a good investment that will last for years. The jackets are made of good fabrics such as wool and wool and acrylic blends to create warm and durable garments. PVC was also used to follow current materials trends and to create some water proofing for the customer. Quilting these fabrics as seen in the samples, gave them a whole new look and added interest and detail to the garments. This detail replaced embellishments as a much cheaper alternative for the diffusion range, for my customer. The leggings are made of elastane and are stretchy and comfortable for the wearer. They can be printed and made in Wellington at several companies giving more competitive pricing. To make up for the expense of digital printing all of the leggings are a consistant and easy pattern to make to reduce labour costs and time.

Instead of using whites, creams and greys I used blacks, greys and some bold colour choices such as a deep purple and blue for several pairs of the leggings. I feel that dark colours work better for winter collections and go with other garments better, so the customer will be happy. The added colour adds interest to the garments and is also keeping up with current colour blocking trend. I feel that purple or blue was best suited as they work well with darker colours and also relate to the slight space age influences I had in my first collection.

The customer that I want to wear my garments is a male in his late teens to twenties, who is interested in fashion and trends, and who may read or write fashion blogs. He would want his clothing to be unique and bold. I wanted the garments to be appealing to this target market, and I feel like have have achieved this, especially because I kept the collection up to date with current trends but it is also unique and original but also remaining socially acceptable and not pushing the boundaries too far for a diffusion line.

In my first collection I used a number of unique material choices, mostly inspired by the 1960s, including worsted fabrics and even metals. For this collection I thought about the customer a lot more and chose to use more appropriate and wearable fabrics. This meant the fabrics need to be warm, comfortable, easy-care and durable, using wool, PVC, acrylic and polyester blends I feel I succeeded in this. I feel the exploration of materials is similar to that of Paco Rabanne as he liked to use new materials and also experiment with old ones to see if he could make something new. He influenced me a lot during my first collection, and I still considered him throughout this collection even though I couldn't push the boundaries in materials to such extremes as metals. For the price range and target market I feel the materials exploration was good.

My refined collection developed from the first collection is for Autumn/Winter 2012 and for the middle to high end markets (a diffusion line). It is a menswear collection for the 15-25 age range. The refined collection has a definite focus on the sewing machine and the mechanics of the machine, however I focussed a lot more on the silhouette of the sewing machine and it's placement in relation to the body in comparison to the first collection which was more about the details. The garments subtly hint that they were influenced by the sewing machine and it's mechanical nature rather than being too obvious and statement. The market influenced my decision for this greatly, because the collection needed to be wearable and socially acceptable, compared to the more expensive high market range which could be very unique and push the boundaries greatly. The diffusion line has boundaries because of what my customers are willing to wear and pay for, and also what society chooses is appropriate. The silhouette and shapes of the garments relate to the curved and square shapes of the sewing machine. These shapes have been emulated within the garments to give my garments a consistency. The target market and my brand influenced this because I want my brand to be recognisable and have a signature look, and so do my customers. Because if someone, specifically someone who is involved in fashion such as a blogger, is wearing a well respected brand they want others to know that they have a garment from there. The shape of the garments is also consistent because then my customers can mix and match any of the garments and make a number of successful outfits. The shape of the jackets was also influenced by my target market. They are made suitable for winter by having long sleeves and being knee length. Layering of fabric is located around chest to keep chest warm and free from wind and cold so the customer can stay healthy. Shape is also between fitted and loose, so that the customer can look thin but also is able to wear multiple layers underneath for warmth.

The garments are on the pricier side of the diffusion market range, but are still affordable to the customer base. The target market should consider my garments to be on trend and a good in season purchase. I want them to be able to continue wearing the garments for years. I hope that the customer considers my garments as a good investment that will last for years. The jackets are made of good fabrics such as wool and wool and acrylic blends to create warm and durable garments. PVC was also used to follow current materials trends and to create some water proofing for the customer. Quilting these fabrics as seen in the samples, gave them a whole new look and added interest and detail to the garments. This detail replaced embellishments as a much cheaper alternative for the diffusion range, for my customer. The leggings are made of elastane and are stretchy and comfortable for the wearer. They can be printed and made in Wellington at several companies giving more competitive pricing. To make up for the expense of digital printing all of the leggings are a consistant and easy pattern to make to reduce labour costs and time.

Instead of using whites, creams and greys I used blacks, greys and some bold colour choices such as a deep purple and blue for several pairs of the leggings. I feel that dark colours work better for winter collections and go with other garments better, so the customer will be happy. The added colour adds interest to the garments and is also keeping up with current colour blocking trend. I feel that purple or blue was best suited as they work well with darker colours and also relate to the slight space age influences I had in my first collection.

The customer that I want to wear my garments is a male in his late teens to twenties, who is interested in fashion and trends, and who may read or write fashion blogs. He would want his clothing to be unique and bold. I wanted the garments to be appealing to this target market, and I feel like have have achieved this, especially because I kept the collection up to date with current trends but it is also unique and original but also remaining socially acceptable and not pushing the boundaries too far for a diffusion line.

In my first collection I used a number of unique material choices, mostly inspired by the 1960s, including worsted fabrics and even metals. For this collection I thought about the customer a lot more and chose to use more appropriate and wearable fabrics. This meant the fabrics need to be warm, comfortable, easy-care and durable, using wool, PVC, acrylic and polyester blends I feel I succeeded in this. I feel the exploration of materials is similar to that of Paco Rabanne as he liked to use new materials and also experiment with old ones to see if he could make something new. He influenced me a lot during my first collection, and I still considered him throughout this collection even though I couldn't push the boundaries in materials to such extremes as metals. For the price range and target market I feel the materials exploration was good.

illustration boards

The first illustration board has a close up of the final jacket of the collection. You are able to seeing the detailing and material easily. The figure is suppose to look like he is being photographed on the street for a fashion blog. I drew a picture of a model walking the opposite way and then edited it on Photoshop and Illustrator to create a silhouette. She is suppose to represent the idea that in my garment you will stand out and be unique compared to everyone else, including models and other people in fashion.

The second illustration board has similar meanings, but features two other men who fit my target market wearing my garments. They are placed further back so that you can see all of their outfit and get a clearer view of the collection. Two photographers, which I edited on Illustrator and Photoshop, are included so that the viewer can more easily see that they are being photographed for a fashion blog.

Here are the original background and photographer images sourced from: weheartit.com and refinery29.com

Sunday 27 May 2012

development of designs

Leggings -

I would like to keep the pants simple and contoured close to the body. This is because the prints looks best when pressed flat and on fabrics such as polyester and elastane blends, which naturally fit to the body. Having wider leg pants would look strange with a pattern and would be difficult to construct with the fabric I have chosen to use. Another reason for the simple leggings is that the jackets are not fitted to the body and therefore the wearer's figure would be obscured by bulky loose fitting garments. At least this way, with the tighter pants contrasting the looser a-line jackets you are able to see the wearer's figure. I like the idea of having similar styled pants and consistent styles of jackets so that the whole collection is easily interchangeable and can be worn together. This is more important in a diffusion line than in a high market range. Note that the images used in the tights are of sewing machine mechanics and parts. These images were taken by me and then edited in Photoshop. Therefore, no legal concerns are present in regards to this, as I first expressed concern over earlier in the project.

fabric choices & sourcing

Fabric and Colour board -

Digital Decor

"Welcome to the world of digital printing

From man's earliest beginnings individuals have aspired to be different and express themselves in unique ways.

This could be achieved by decoration, which might include his body, clothing, or his home. Primitive man made cave paintings to depict their lives, or record special occasions, becoming the first interior decorators.

For centuries interior decoration was created by artisans and craftsmen as single piece art works, often commissioned by the wealthy or the church.

The industrial revolution heralded mass production of items previously unavailable to the masses. Soon everybody could have the same matching clothing, homeware and interior design. Individualism was lost!

For centuries interior decoration was created by artisans and craftsmen as single piece art works, often commissioned by the wealthy or the church.

The industrial revolution heralded mass production of items previously unavailable to the masses. Soon everybody could have the same matching clothing, homeware and interior design. Individualism was lost!

The Age of Mass Customisation

Digital printing has heralded the age of mass customisation. Giving many individuals who aspire to put their unique thumb print on their surroundings, the opportunity to achieve this at an affordable cost.

Digital Décor works with architects, designers, photographers, artists and individuals to create exclusive custom designs on a range of fabrics, tiles and other substrates so your living space can be transformed into a work of art.

Digital Décor works with architects, designers, photographers, artists and individuals to create exclusive custom designs on a range of fabrics, tiles and other substrates so your living space can be transformed into a work of art.

Digital textile printing technology is revolutionizing the textile industry, with many new market opportunities opening because of the flexibility of small runs or one-offs of custom designed textiles.

Traditional textile printing industry mass production model of high volume and low cost are being challenged by designers, artists, interior designers and architects who want to create imagery and designs which are exclusive, original and unique. Digital Décor's™ ImagedFabric™ is meeting these inspired individuals needs.

The traditional textile printing processes have disadvantages of high setup costs, limited colours, long turn around times and small quantities are often uneconomical.

Digital printing has none of these disadvantages, with minimal set up costs, unlimited colours, superb photographic print quality, quick turn around of samples, final production and one offs if necessary.

Digital Décor™ textile printing should be seen as short run, customized production of textiles. Prints can be richly detailed designs of unlimited colours, special photos, a favourite painting, company logo or any other digital artwork. We mainly print on polyester fabrics, because of their durability, easy care, light fastness and UV stability. Polyesters can be made to look and feel like many other fibres; silk, linen, cotton, wool and suede. Plus will perform better.

We welcome the opportunity to work together with your own designs for exclusive ImagedFabrics"

We welcome the opportunity to work together with your own designs for exclusive ImagedFabrics"

Digitex

Lead the way with digital textile printing.

Digital Textile Printing is revolutionizing the textile industry worldwide. Traditionally textile printing has been based on a mass production model where fabrics are produced by rotary screen printing in large volumes. The benefit of this method was high volume product at a low price. However there are many disadvantages to traditional textile printing. These are high setup costs, lengthy and expensive sampling process, slow turn around, limited number of spot colours per design and short runs

Digital Textile printing is the key to opening new markets. It does not have any of the disadvantages of Traditional Textile printing while offering the ability to use an unlimited number of colour's, excellent reproduction of continuous tone images, unlimited repeat sizes and the ability to print multiple designs.

Standard Fabrics

We can print up to 1600mm wide from the roll on to:

• Cotton

• Silk

• Polyester

Supplying fabric

There are some limitations on the type of fabrics that are suitable for digital textile printing and it is important that you talk to us to discuss your needs. As as guide we can accept almost any 100% polyester fabric you supply, however all other fabrics such as cottons and silks must be pre-treated before printing.This pre-treatment process requires a minimum of 50 meters of fabric.

How best to take advantage of Digital Textile Printing

When considering how best to take advantage of Digital textile printing it needs to be looked at it from the perspective of a short run, customized production of textiles. The traditional textile industry looks at digital textile printing from the perspective of what it can’t do, rather than from the perspective of the new markets it will allow them to enter. The challenge to the textile industry is in learning both the digital printing technology as well as a new business model under which to sell their products.

Implementing digital printing effectively means rethinking your overall system. It means designing different types of products that leverage the advantages of digital printing. It means sales and marketing strategies that leverage short run production. It means thinking about your business from the perspective of mass customisation as opposed to mass production.

Think outside the box

Bottom line, digital printing for short run production requires thinking outside the box. It requires an entirely new approach with new products and new marketing strategies that leverage not just printing technology, but CAD systems, cutting systems, information systems and even the Internet.

The Advantages of Digital Textile Printing

To make the most of Digital Textile Printing its important to understand it capabilities and focus on value not cost.

- Multiple colour-ways

- HUGE Reduction of Downtime

- Just in time delivery

- Shortens the overall process from design to production

- No engraving

- No finished goods inventory

- Allows Mass Customisation

- Elimination of Screen Cost in Sampling and Short-run production

- No more registration problems

- Elimination of Costly Machine Strike-offs

- Eventual Reduction of Chemical Cost and Waste

- Brings New Products to Existing Markets

The myth about speed and price

The traditional textile industry looks at digital textile printing from their traditional mass production business models and complains it is too slow and too expensive relative to the conventional screen printing technologies most commonly used in the market today. This is failing to recognise the

opportunities and savings digital textile printer offers.

Cost Savings of Digital Textile Printing

| To date, the key drivers in adopting digital textile printing technology for traditional textile printers has been the reduction of sampling costs and time to market. In conventional textile screen printing, the development cost for strike-offs and samples are thousands of dollars per design, with the cost fluctuating based upon the number of spot colours used in a design. The development of these screens and strike-offs takes from 2 to 5 weeks. With digital textile printing there are no screen costs, and a sample can be printed upon demand. |

Just in time delivery

The single most costly element in today’s soft goods business is the holding of product and parts in anticipation of a sale. This process supports the idea that the best way to create profit is to mass produce and discount the surplus. To make this gamble work the apparel delivery system has developed cumbersome structure designed to stockpile the inventory in staged production surpluses, then to sell finished product in tiered discount and therefore reduce the risk for each participant. While this process has in fact lowered cost, it has also lowered profit and customer choice.

Become an industry leader

Leaders in Digital Textile printing are looking at this technology with an eye towards what it can do, as opposed to what it can't do:

- Offer a unique print and selling point

- Offers Immediate Results

- Offers Flexibility

- Saves Time & Money

- Minimizes Inventory

- Is A Breakthrough Technology

- Allows Mass Customisation

Other fabrics freely available in Wellington City through such stores as Global Fabrics where my fabric was bought from.

Wednesday 23 May 2012

fabric analysis and samples

fabric research

Polyester

• Resilient and easy care

• Machine washable due to dimensional stability

• Blends well with other fibres

• Superior aesthetics to Nylon

• Light in weight and dries quickly

• Exhibits moderate thermal retention. It is generally not as comfortable as wool or acrylic for cold weather wear

• Blends with wool are very successful in increasing the comfort of the wool

• Polyester has an advantage over wool in many uses, since wool has poor wrinkle recovery

• Resiliency makes the polyester especially good for fibrefill in quilted fabrics such as quilts

Wool

• Because of wool’s high initial cost and the cost of care, many consumers consider them to be investments

• These factors have encouraged the substitution of acrylic, polyester, or wool/synthetic blends in many products

• Good moisture absorption without feeling wet

• Excellent heat retention

• Water repellency

• Flame resistant

• New Zealand produces 18.8 percent of the world’s wool

• Durable

• Wool fibres can be bent back on themselves 20,000 times without breaking, as compared to 3,000 times for cotton and 75 times for rayon

• Atmospheric moisture helps wool retain its flexibility

• In a light rain or snow, wool resists wetting and the water runs off or beads on the surface

• Wool’s excellent resiliency contributes to its warmth

• Wool does not soil readily and the removal of soil from wool is relatively simple

• Dry cleaning is the recommended care method for most wool items

• Renewable resource and environmentally friendly

• Wool garments fit well and can be shaped through tailoring

Cotton

• Aesthetically pleasing

• Comfortable for skin contact due to high absorbancy

• Easy care

• Moderate cost

• Ideal for warm weather apparel, but is appropriate for year round use

• Consumer acceptance

• Low resiliency

• Limited shrinkage

• Cotton can be washed with strong detergents and

• Cotton blended with polyester is a very wrinkle resistant fabric

• Ease of finishings and dyeing

Nylon

• Successful in hosiery and knitted fabrics due to its smoothness, light weight, and high strength

• Outstanding durability

• High elongation and excellent elastic recovery excellent for hosiery

• Nylon can be heat set which helps it retain its shape during wear

• Nylon is used for lining fabrics in some coats and jackets. They are more durable, however, the cost is greater because of the greater difficulty in sewing and higher costs as compared with acetate fabrics.

• Has low absorbency and is not as comfortable to wear as natural fibres

• Widely used for wind and water resistant jackets

• Highly resilient because they have been heat set

• Easy care as they retain their appearance and shape during use and care

• Nylon fabrics can pick up other colours during washing

• Dries quickly

Acrylic

• Soft and rather comfortable due to irregular surfaces

• Bulky fabric retains body heat so are warm in cold temperatures

• Because of their low specific gravity and high bulk, acrylic has been called “warmth without weight”

• Resilient but not as durable as nylon or polyester

• Acrylics are used for sweaters as an alternative to wool

• Superior to wool in their easy care properties and nonallergenic

• Wool-like texture

• Not as heavy as wool

• Poor dimension stability

development of designs

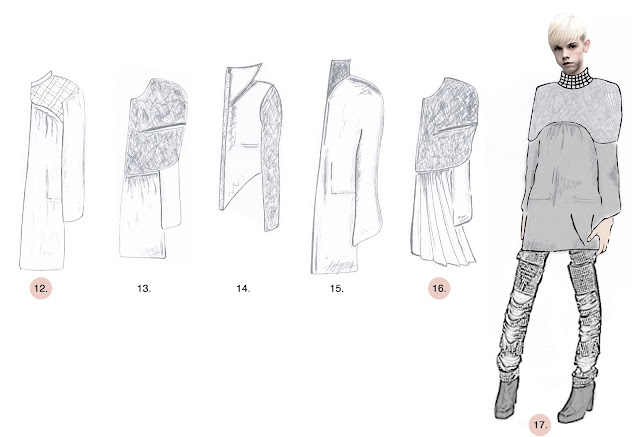

Deciding on collection line up order -

Final line up order -

• The designs begin simple and structured

• They are evenly structured with as much weight given to the top as to the bottom.

• The lengths are varied but are generally situated around knee length

• Quilting is added during the middle of the collection

• Pockets for practically for customers

• Range of fabrics for quality but also affordability

• Oversized lapels and collars for dramatic features to appeal to the customer base

• These features relate to the concept and to the original collection designs

• Outer shape of the sewing machine's silhouette is obvious throughout the designs

• The shapes of the intricate details of the sewing machine, e.g the needle and foot can be seen within these designs

• Pleating added to final garment to make it the most complex and detailed garment. Would likely be most expensive

• Slightly a-line shaped jackets

• Focus generally drawn to one part of design specifically. In most cases, the top half of each garment

• All with sleeves for warmth in winter

• Practical and versatile for customers

• Varied fabrics, but consistent use so that each garment relates to the rest

Saturday 19 May 2012

summary of designs

Designs from original garments -

Designs from jacket & tailoring research -

Designs developed from originals and research above -

Note - all above garments are designed in sequence, with each design being developed upon by the one after it.

7. Inspired by first garment from the first collection. Very simple. Will not develop further.

8. Inspired by second garment from the first collection. High collar and needle inspired shaping could be developed into new designs.

9. Inspired by third garment from the first collection. The lack of second sleeve could prove problematic for a winter garment. This feature may also look strange with heavier winter fabrics.

10. Inspired by forth garment from the first collection. The front panel would be printed with an image, which would make the otherwise simplistic garment more complex.

11. Inspired by fifth garment from the first collection. The metal rods on the arms are too ambitious for a diffusion line. The cost and comfort would be compromised if metal was used.

18. The top shape curves into left arm sleeve and is very unique. Adds interest and appeals to target market who want original designs.

19. The absence of fabric on the shoulder is original but I do not like the neck line on this garment, as the triangular shape has no relevance to my concept or other designs.

20. I find the half collar to be a very original feature, however structurally this would be difficult and therefore costly to construct. I don't particularly like how it looks however that is just my personal taste and not my customers thoughts also. Others that I should the design to liked the collar a lot. I therefore may include the design for development, depending on if it relates to the other designs.

21. This jacket is very symmetrical in comparison to many of the other garments. It would be one of the first pieces I would show in my line-up as it is simple, understated, even, and considered very wearable for most consumers. This is compared to some of the more original designs with uneven tailoring, oversized lapels and statement collars.

22. Developed from design 21. Bold shaped rectangle is contrasting in placement to the two found on the design before. Dropped shoulder seam.

23. Bold statement lapel. Oversized and eye catching. Added warmth over chest area via layering of lapel over the jacket fabric.

24. Shortens and angles the lapel from design 23. This one is probably more original and makes it more unique from the other designs via the angle the lapel is placed upon.

25. This design is too top heavy and takes away any shape the jacket gives. Introduction of quilting is effective, but becomes overwhelming when located on the sleeves.

26. Simple and elegant design. Longer length and somewhat tight fitted shaping. Successful and I would like this to be one of my final garments. I don't want to change the design at all, but could explore fabric selection further. Quilted top gives the simple and even design a element of added interest without being overpowering. In season design.

27. Developed from designs 2 and 8. Quilting placement continued from design previous design.

28. Keeping of quilting in same place while statement collar is removed and needle shaping is moved to add interest to the sleeve. Currently the sleeve is open to expose the arm or under layers, but this could be changed later if desired.

29. This design is too complex and busy. There is too much quilting. I would prefer if it was a small design feature on several of the garments rather than a majority fabric choice.

30. Slightly uneven placement of front pockets adds interesting detailing, especially considering their low placement and quilted fabric. The eye is drawn down the garment to these which I like. The long length is slimming.

31. There is too much quilting. I do like the placement of the pockets, so low that they almost hang off the jacket. I would probably take the pocket design and put them on a different jacket if I was to develop this further. Dropped shoulder seam.

designs developed from original concept

During the first assignment several garments had detailing inspired by the sewing machine's needle, as it is such a vital part of the functioning sewing machine. The foot of the machine is also a very important aspect and is an intricate detail compared to the more obvious general shape of the machine. I would like these two parts of the machine to influence the shape of the garments and the detailing, e.g collars. By keeping the high collars and the needle shape from the first collection I am creating consistency amongst my designs and am making a signature look that can be seen through the high market collection and this new diffusion line.

Sunday 13 May 2012

designs

As I really like the idea of printed images on garments, but I think it would be overwhelming on jackets, I have created some conceptual designs on leggings. I have used images from my work so far and the pants seem very relevant to my concept. I doubt that I will use these images in my final collection however as the images are not copyright free and therefore that would be not only illegal but also unethical. I would like to take my own photographs or draw designs, or perhaps find appropriate copyright free images.

I think that the skinny style of the leggings is something that I would like to keep in my final collection, as the silhouette created by the skinny pants paired with the oversized jackets looks good in menswear. It also relates to the idea of the sewing machine, as the outer case (e.g the jacket) is bulky and clean with straight lines compared to the smaller components (e.g leggings) that are intricate and have a lot of detail.

Subscribe to:

Posts (Atom)